CG007 Godzilla Automotive Key Cutting Machine Support both Mobile and PC with Built-in Battery

Product Description

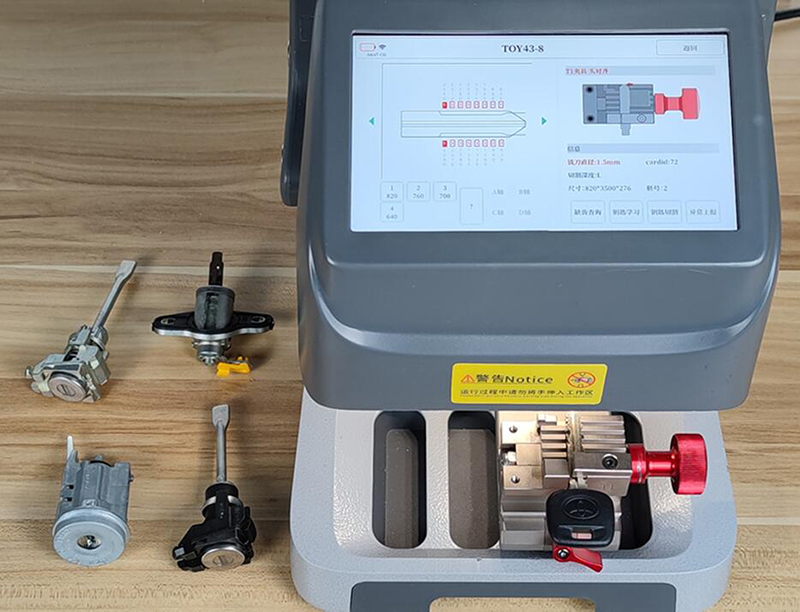

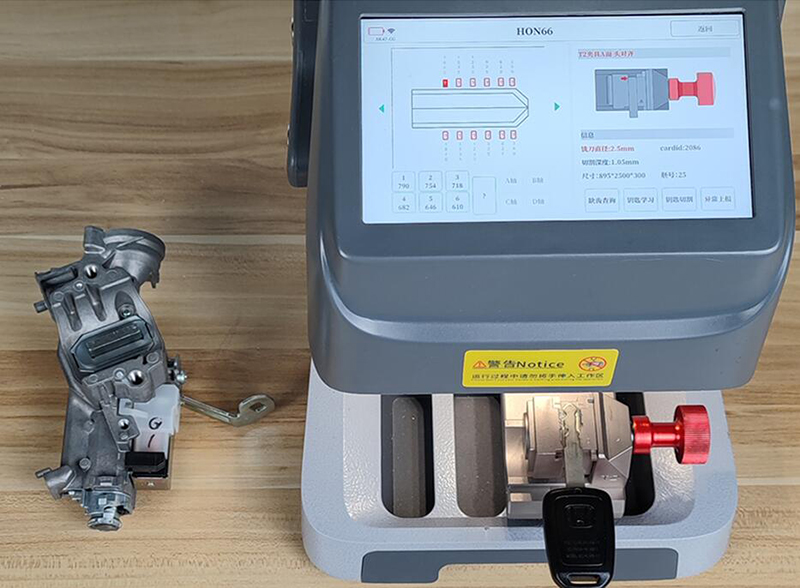

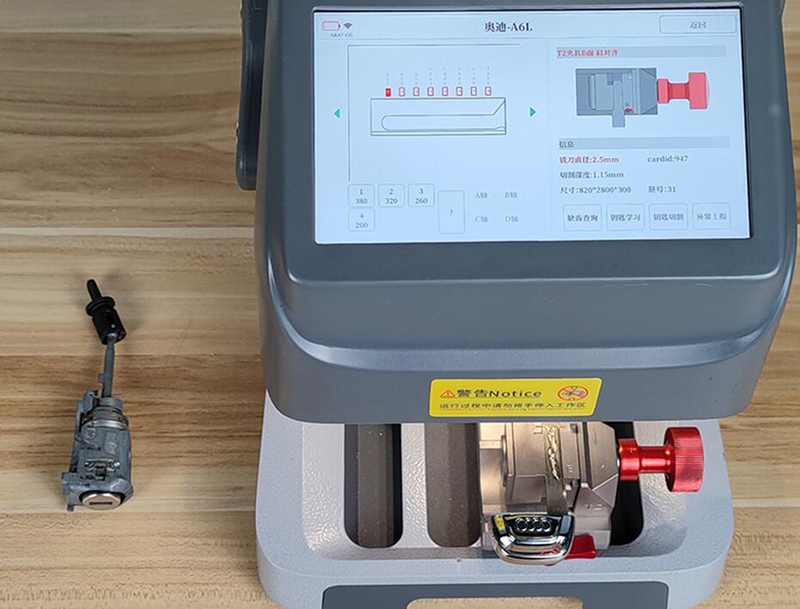

The Godzilla portable key CNC processing machine has the characteristics of convenient carrying, super performance, and novel design. It is a new generation of key processing equipment tailored for locksmiths around the world. It is equipped with a 7.0-inch LCD capacitive touch screen, which is easy to operate and can Copy and process all kinds of car keys quickly and accurately.

Specifications

Input voltage:100~240VAC

Input frequency:50/60Hz

Maximum power:160W

Spindle speed:12000rpm

USB interface:Micro USB

Working temperature:-20~50°C

Operating humidity:10~90%

Machine net weight:13kg

Total packaging weight:16kg

Machine size:348*225*328mm

Packing size:580*340*420mm

Features

Godzilla key cutting machine is a new generation of portable key CNC processing machine, the product has the following characteristics:

1.Portable and compact, built-in large-capacity lithium battery, long battery life.

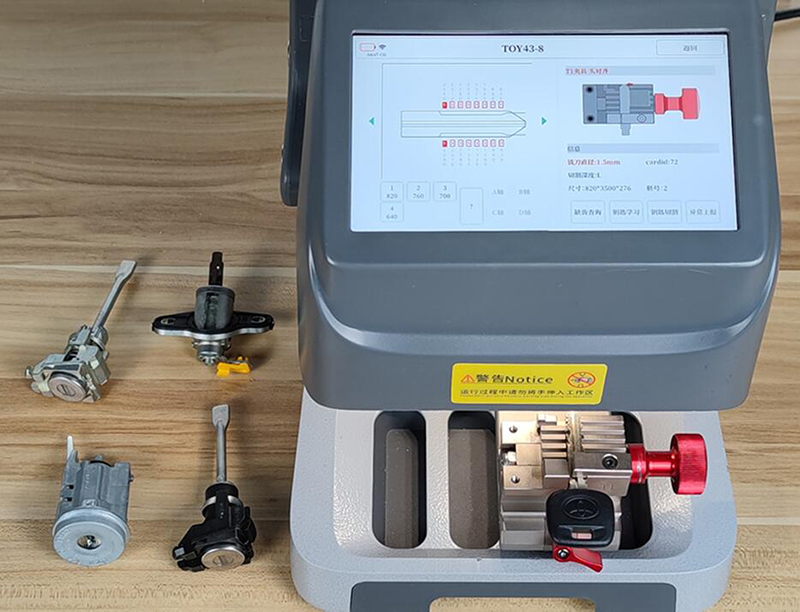

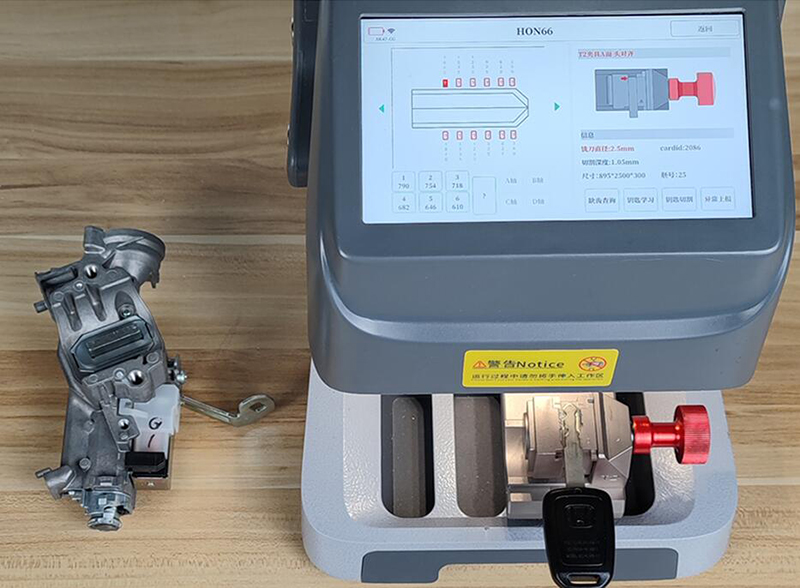

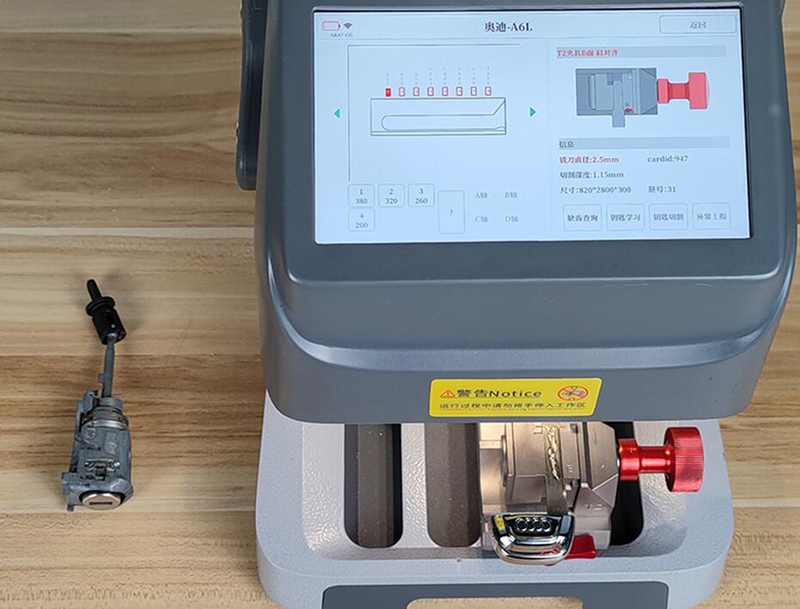

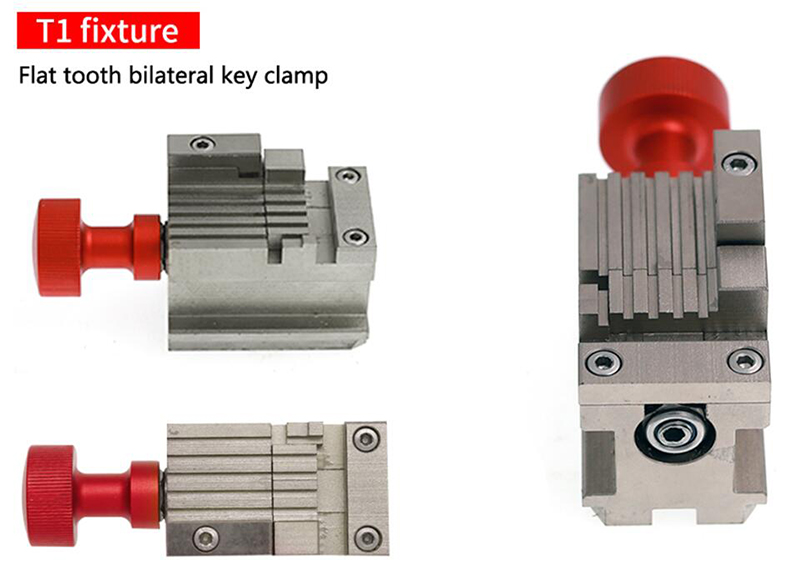

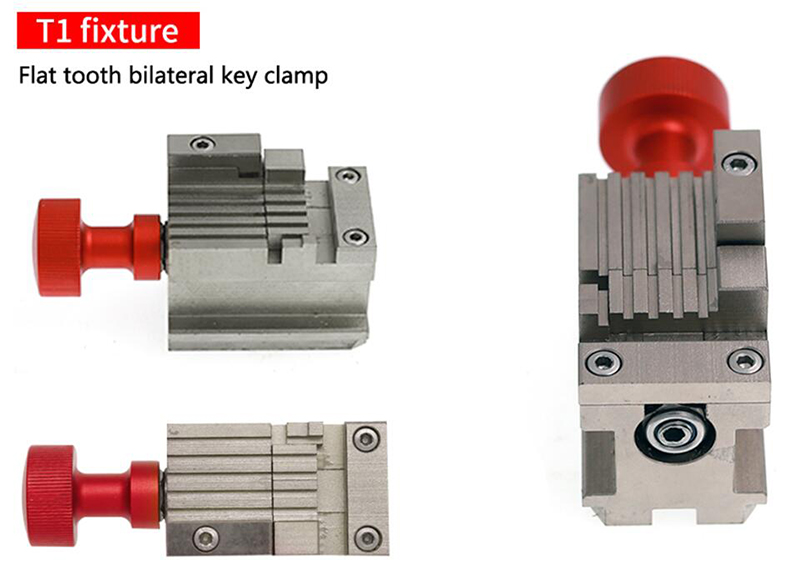

2.Standard T1 and T2 double fixtures.

3.Support operation modes such as external washing and internal milling.

4.All-aluminum structure body.

5.Imported high-precision screw rod, high cutting efficiency.

6.High-rigidity cross guide rail, running more smoothly.

7.Support multiple languages.

8.Mass database.

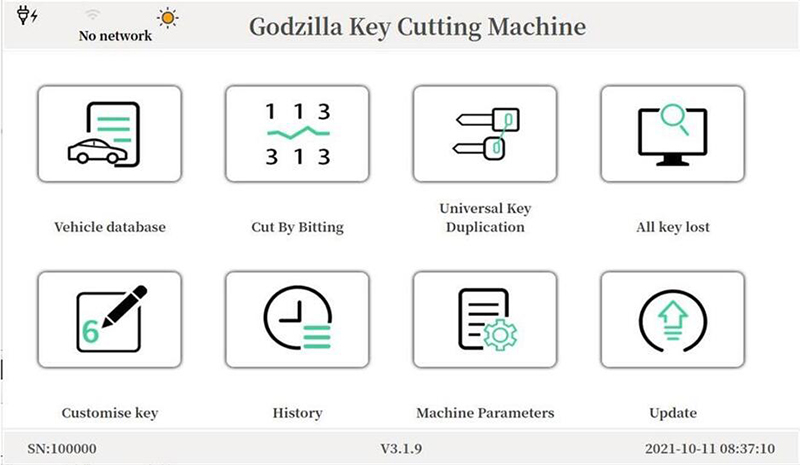

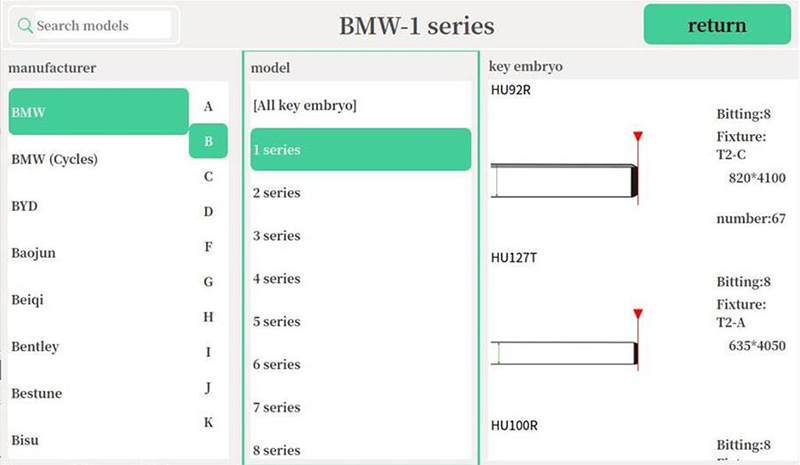

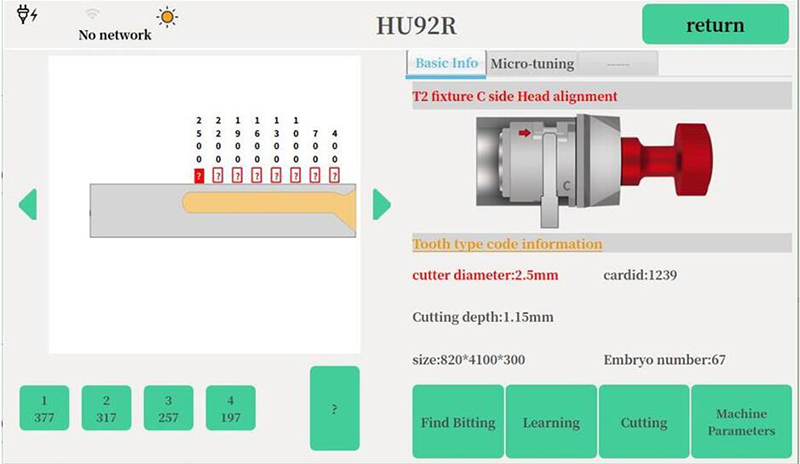

ar Database

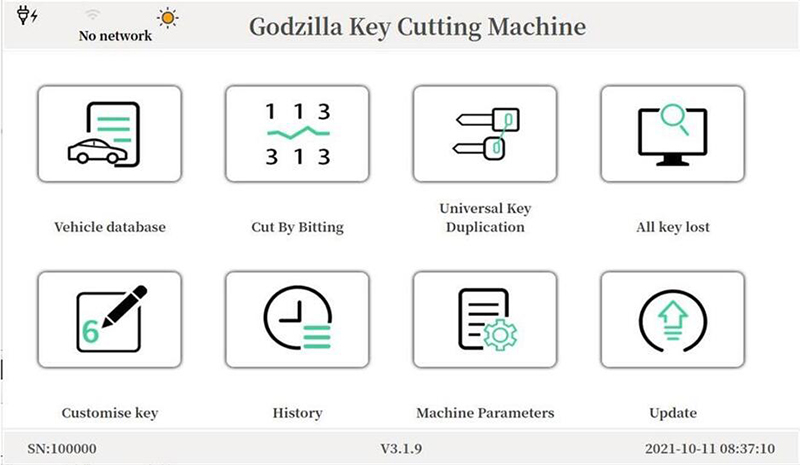

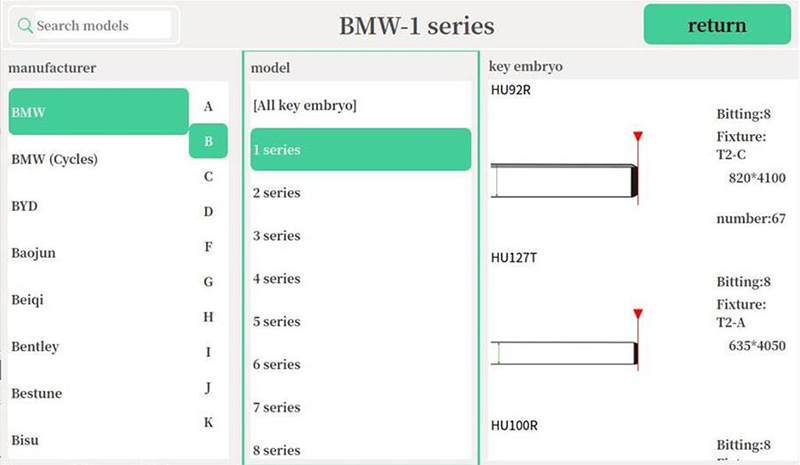

Massive car brand model key data, including European, American, Japanese, Korean, domestic and other global cars, learn and cut according to the data selected by customers, and support missing tooth query and tooth profile fine-tuning functions.

Support car manufacturers are as follows:

Mitsubishi, Hyundai, Volvo, Honda, Holden, Jeep, Opel, Vauxhall, Chrysler, Dodge, Daihatsu, Suzuki, Jaguar, Audi, Rover (also see Brit.Leyland), Mazda, Nissan, Toyota, Duka Di, Saab, Subaru, BMW, Alfa Romeo, Fiat, Renault, Peugeot, Yamaha, Chevrolet, MG, Scania, Volkswagen, Ferrari, Lamborghini, Maserati, Seat, Iveco, Mercedes-Benz, Lexus, Porsche, Citroen, Lincoln, Mercury, Infiniti, Kia, Buick, Cadillac, Rolls Royce, Daewoo, Acura, Bentley, Ford, Land Rover, Skoda, Ssangyong, LDV, Mini, BMW Motors, Honda Motors, General Motors, Jiangling, Great Wall, Haval, Geely, Changan, Roewe, Lifan, Baojun, Zotye, Haima, Huasong, FAW, Southeast Motor, Pentium, BYD, Wuling, Bugatti, Dongfeng, JAC, Chery, China, Cheetah, Trumpchi, Mustang, Jinbei, Bispeed, SAIC Hongyan, Landwind, BAIC, Dongfeng Qichen, Shaanxi Heavy Truck, GMC, Baowo, Zhidou, Chase, Nazhijie, WEY, Isuzu, Qoros, Hantang Electric Vehicles, Genie, Hummer, Hafei, Sinotruk , Jiefang, Hongqi, Bi Devon, Buluda, Lynk & Co, Reading, Dongfeng Scenery, Dongfeng Fengshen, Dongfeng Fengxing, Dongfeng Xiaokang, Foday, Fuqi Qiteng, Foton, Huanghai Automobile, Zhongxin Electric Vehicle, Dongfeng Manner, Universiade, Shaanxi Auto, SW, ZTE, Suzuki (motorcycle)

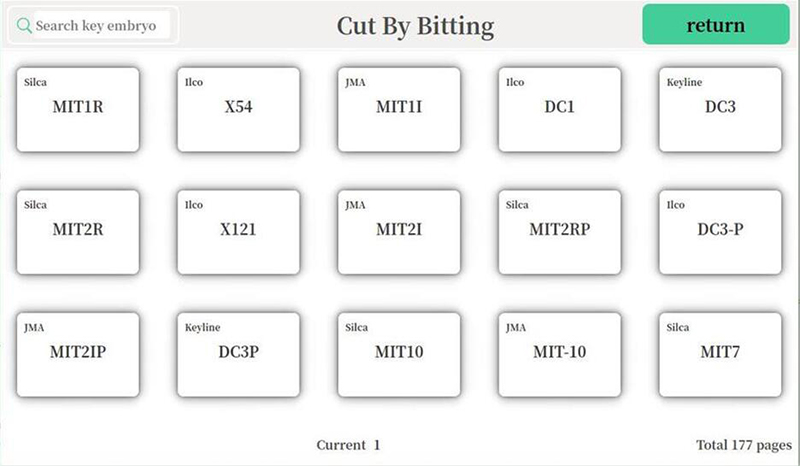

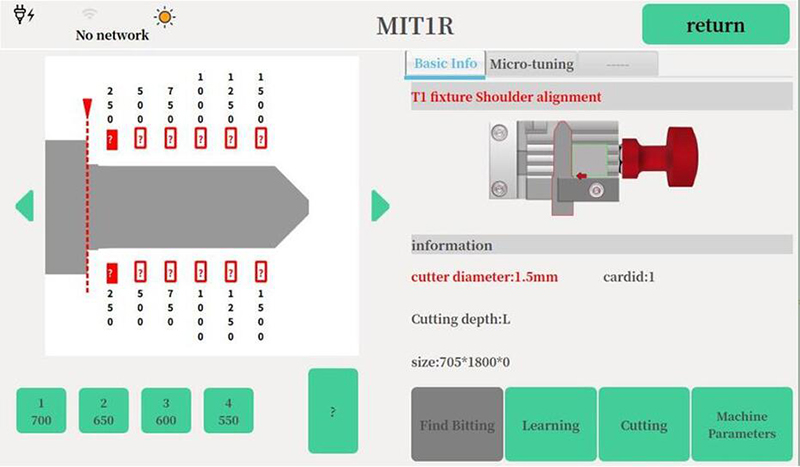

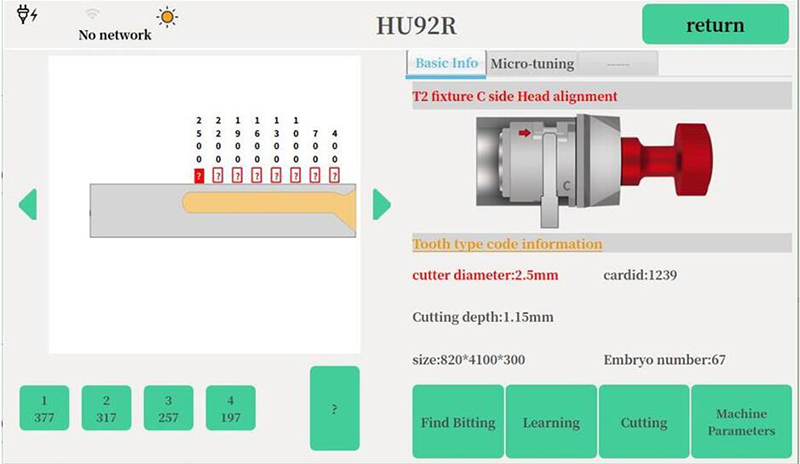

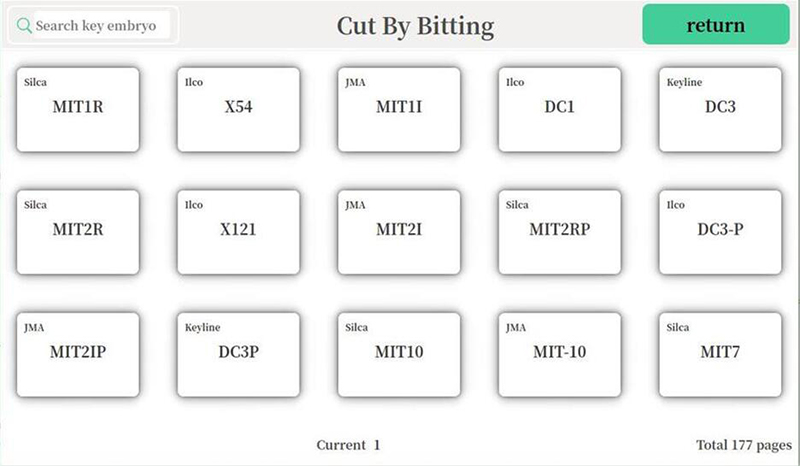

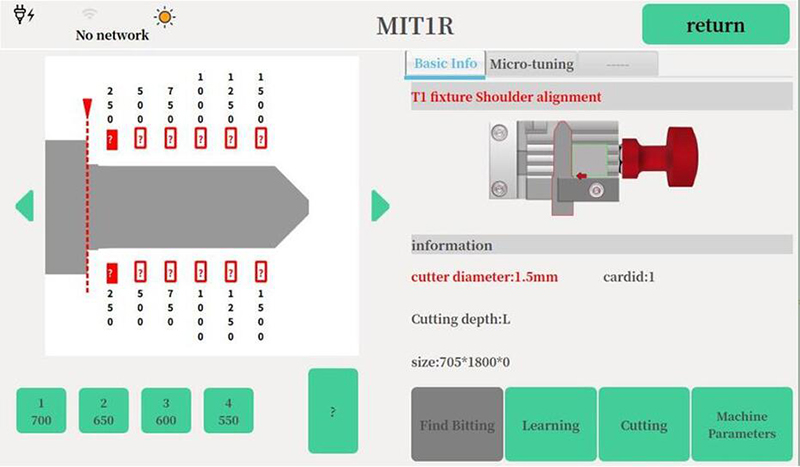

Tooth Code Processing

Contains mainstream key models, which can be learned and cut according to the customer's key model, and supports missing teeth query and tooth profile fine-tuning functions.

Some models supported are as follows:

Silca MIT1R

Ilco X54

JMA MIT1I

Ilco DC1

Ilco X174

Keyline TR42

Silca TOY38RAP

Keyline TR42BP

Silca TOY41RATE

Keyline TR41TK

Silca TOY41RTE

JMA SUZU-8P

Keyline SU17P

Silca SZ11RT18

Silca SZ11REH2

Keyline SU17UTK40

Silca SZ11RMH

Silca SZ11RTE

Keyline SU17TK

Silca SZ11REH1

Keyline SU17UTK24

Silca SZ11REH

Keyline SU17U

Keyline SU17UTK100

Silca SZ11RT4

Keyline SU17TK3

Silca SZ11RT5

Keyline HU35UTK60

Silca HYN5R

Ilco X196

Silca HYN5RP

Ilco TA28

Silca TOY4

Ilco T61C

Ilco T61G

JMA TOYOK1

Keyline TR14

Silca TOY6

Ilco T61D

Silca SSY2AP

Silca KIA1R

Ilco X233

Silca KIA1RAP

Keyline KI1SAP

Silca KIA1RP

Ilco KK1P

Keyline KI1SP

Silca KIA2R

Ilco X240

Silca KIA3RT5

Ilco KK3P

Keyline KI3STK1

Silca SSY1P

Silca MIT3R

JMA MIT3

Silca MIT3RP

JMA MIT3P

Keyline MT5SP

Silca MIT4R

JMA MIT4

Silca TOY24P

JMA TOYO8P

Keyline TR4P

Silca TOY25

JMA TOYO3

Silca TOY25P

JMA TOYO3P

Keyline TR5P

Silca TOY36AP

Silca TOY36P

Silca ISU3P

Keyline ISU2P

Silca KW11

Ilco KA13

Silca MAZ10AP

Keyline MZ32P

Silca MAZ5

Ilco MZ14

Silca MAZ8

Ilco 929M

Silca MAZ8AP

Keyline MZ38P

Silca KIA4RBP

Silca HYN11

Silca HYN11CP

Keyline HY11BP

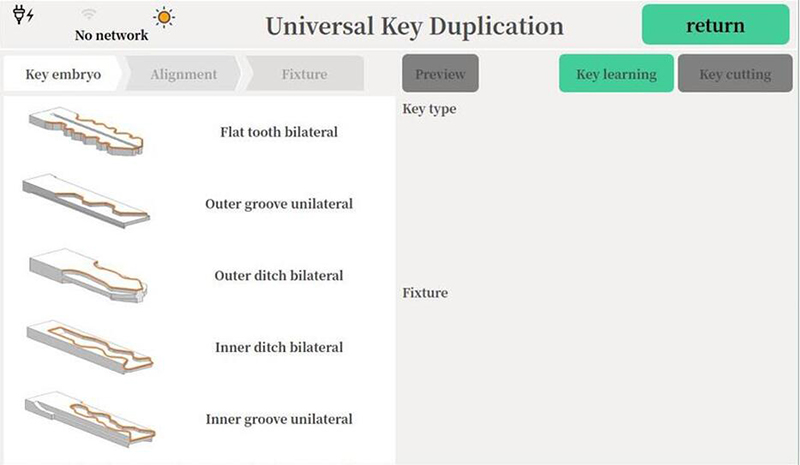

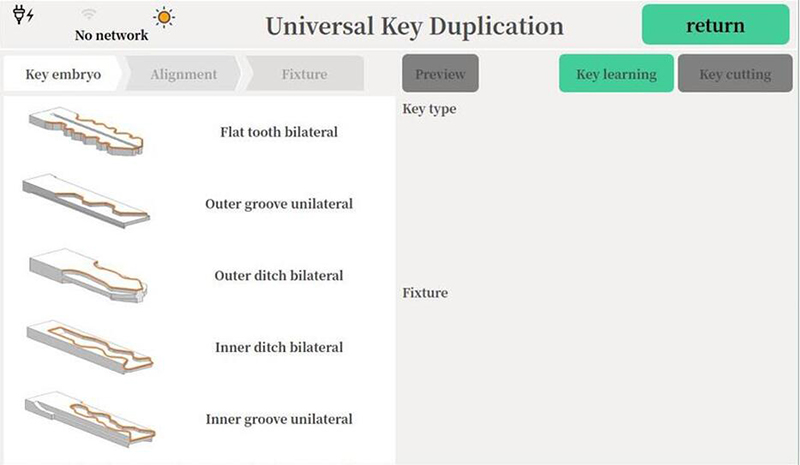

Universal Key Copy

Accurate learning according to the shape of the car manufacturer's key and precise cutting according to the learned shape.

Waigou bilateral: mostly used in Japanese, Korean and domestic cars

Inner ditch unilateral: mostly used in European and domestic cars

Neigou bilateral: mostly used in Japanese, Korean and domestic cars

Outer ditch unilateral: mostly used in European, American and domestic cars

Waigou bilateral: mostly used in Japanese and domestic cars

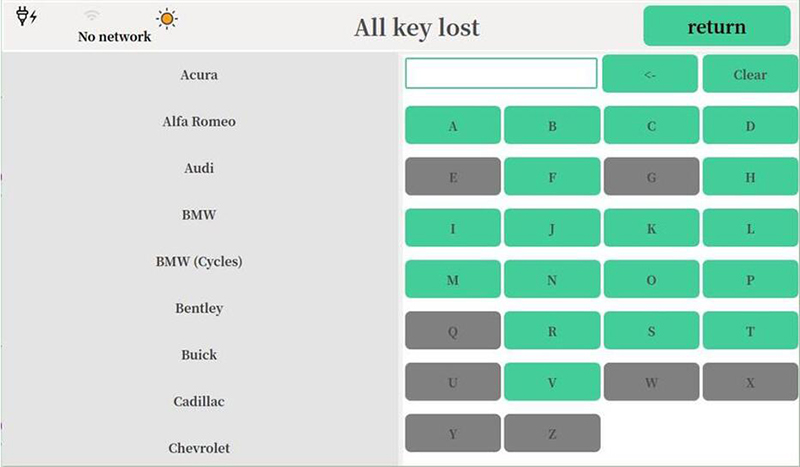

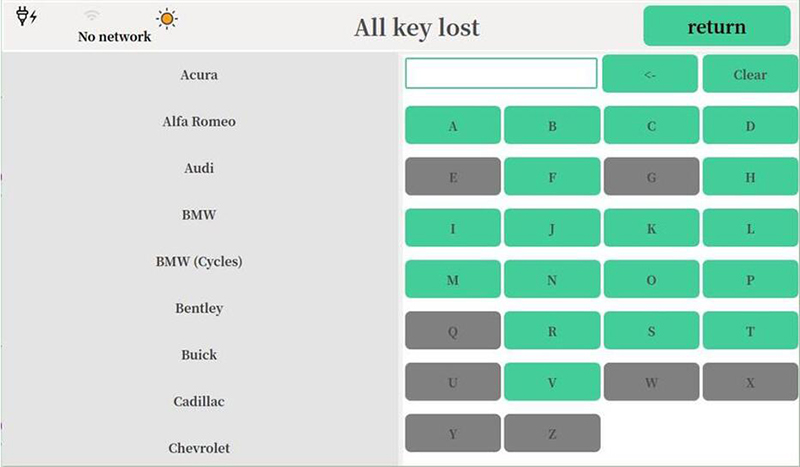

Lost All Query

Covering the key data of mainstream brands such as European, American, Japanese, Korean, etc., the key tooth profile data can be found by using the manufacturer code or the lock cylinder code.

Support car manufacturers are as follows:

Mitsubishi, Hyundai, Volvo, Honda, Holden, Jeep, Opel, Vauxhall, Chrysler, Dodge, Daihatsu, Suzuki, Jaguar, Audi, Rover (also see Brit.Leyland), Mazda, Nissan, Toyota, Duka Di, Saab, Subaru, BMW, Alfa Romeo, Fiat, Renault, Peugeot, Yamaha, Chevrolet, MG, Scania, Volkswagen, Ferrari, Lamborghini, Maserati, Seat, Iveco, Mercedes-Benz, Lexus, Porsche, Citroen, Lincoln, Mercury, Infiniti, Kia, Buick, Cadillac, Rolls Royce, Daewoo, Acura, Bentley, Ford, Land Rover, Skoda, Ssangyong, LDV, Mini, BMW Motors, Honda Motors, General Motors

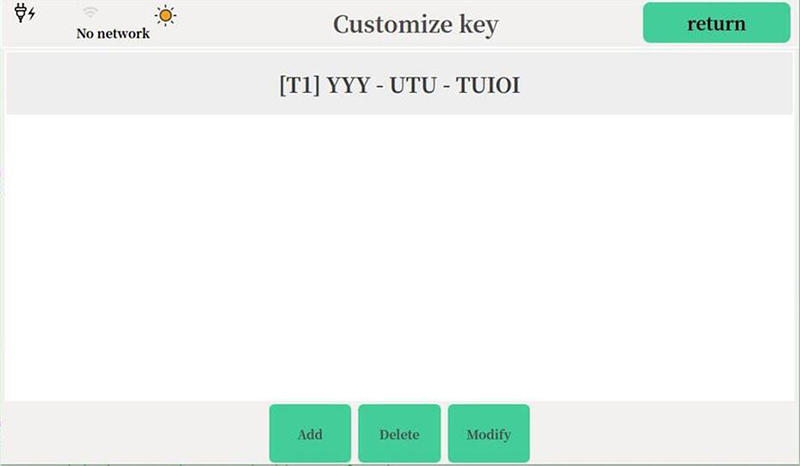

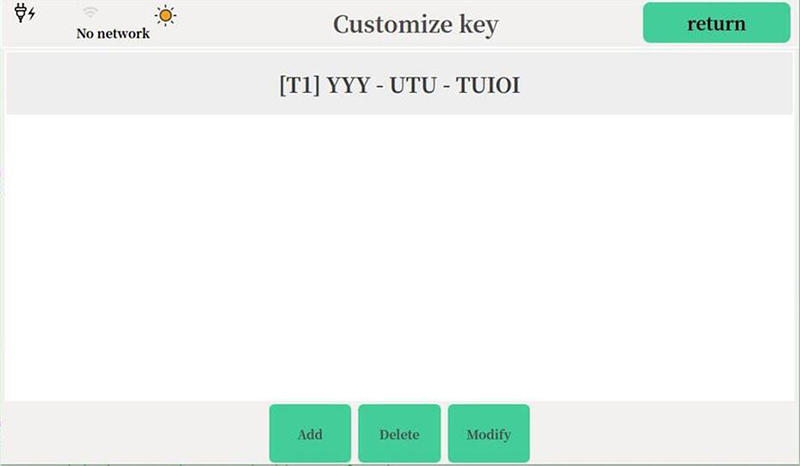

Custom Key

Key processing is performed according to the data defined by the customer.

Waigou bilateral: mostly used in Japanese, Korean and domestic cars

Inner ditch unilateral: mostly used in European and domestic cars

Neigou bilateral: mostly used in Japanese, Korean and domestic cars

Outer ditch unilateral: mostly used in European, American and domestic cars

Waigou bilateral: mostly used in Japanese and domestic cars

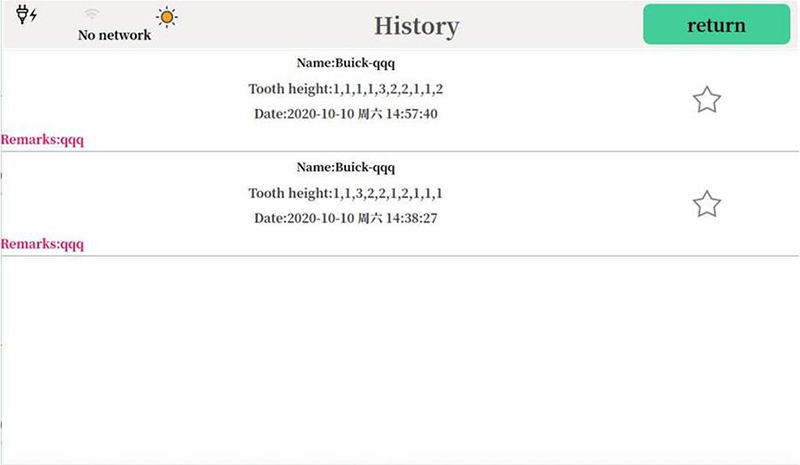

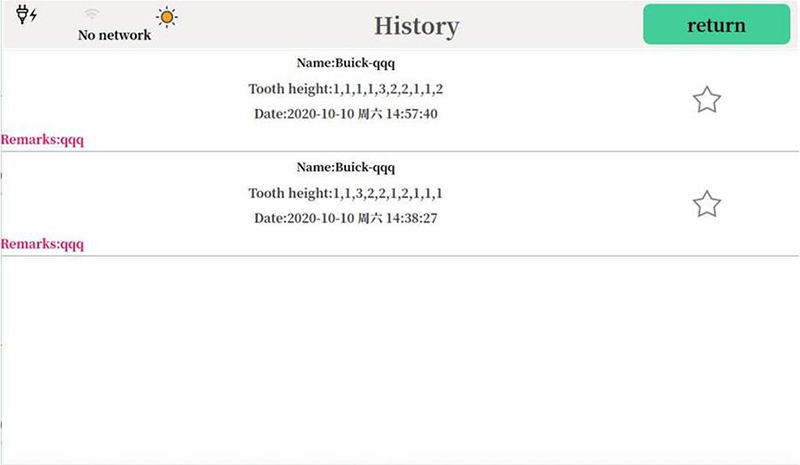

History Record

After the key is cut in the database, the device automatically stores the data of the cut key, which can be marked and placed on top according to customer needs.

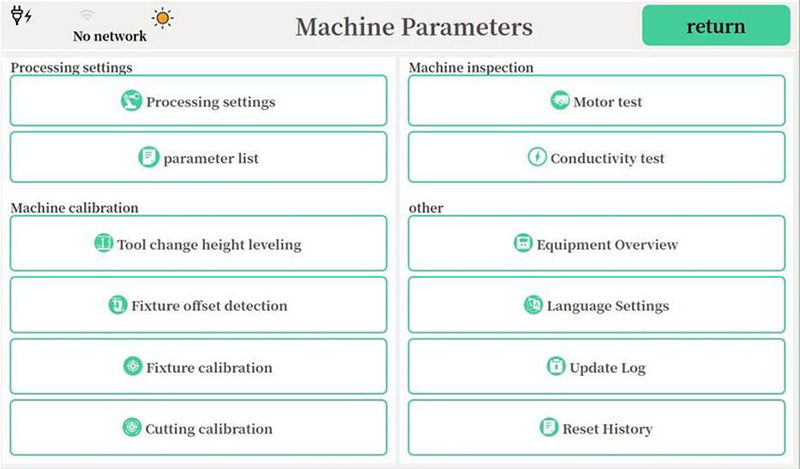

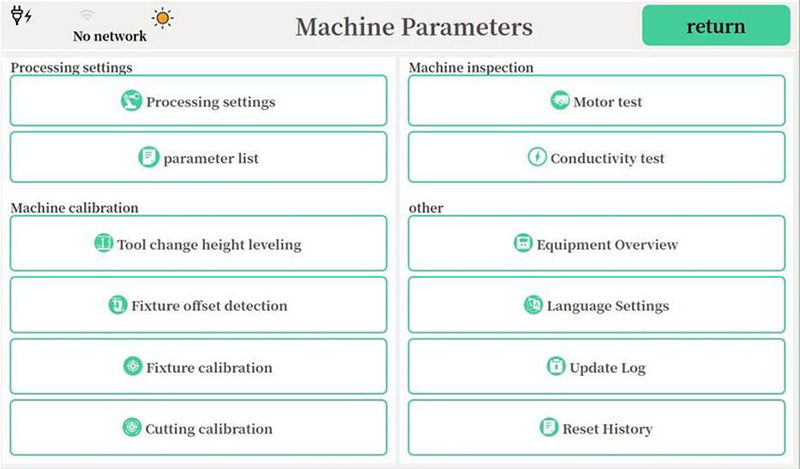

Device Parameters

Contains processing settings, parameter lists, automatic calibration, test functions, cutting times statistics and language settings. Customers can set and adjust processing settings according to their own requirements. Visualize equipment parameter list data. If there is an error in learning cutting, you can operate the calibration function to calibrate it. It can test the active motor of the equipment and automatically determine whether the motor is normal. The equipment automatically counts the number of cuttings. Contains four languages.

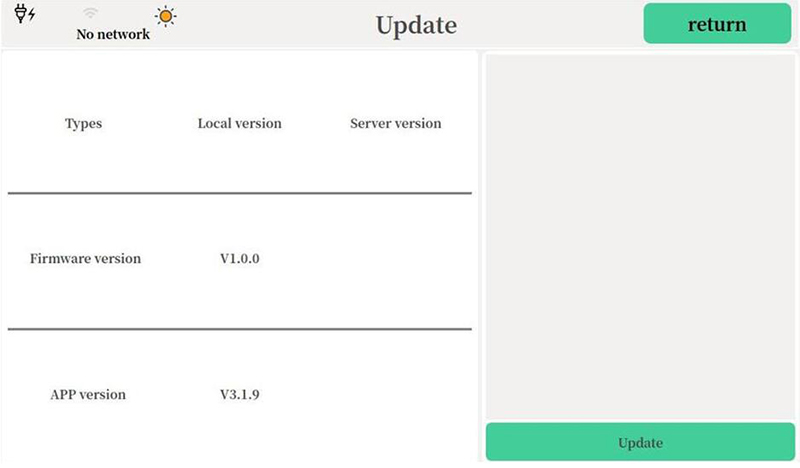

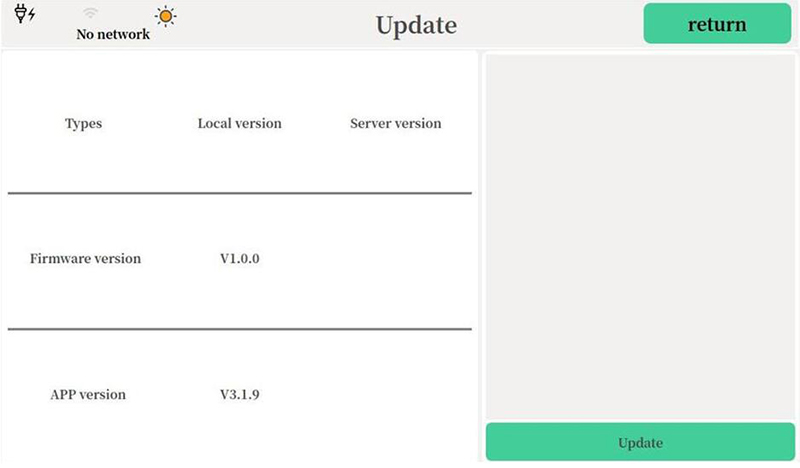

New Version Update

Add functions and data to update the software according to customer feedback and needs.

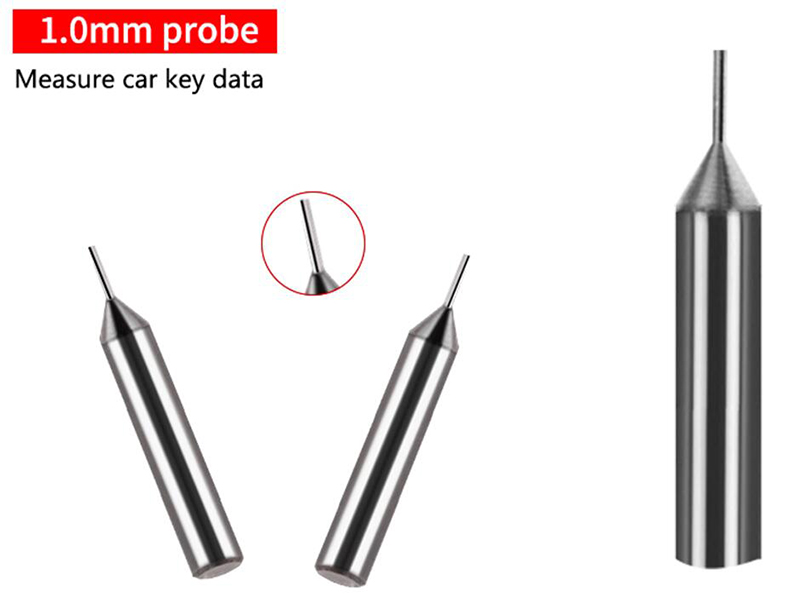

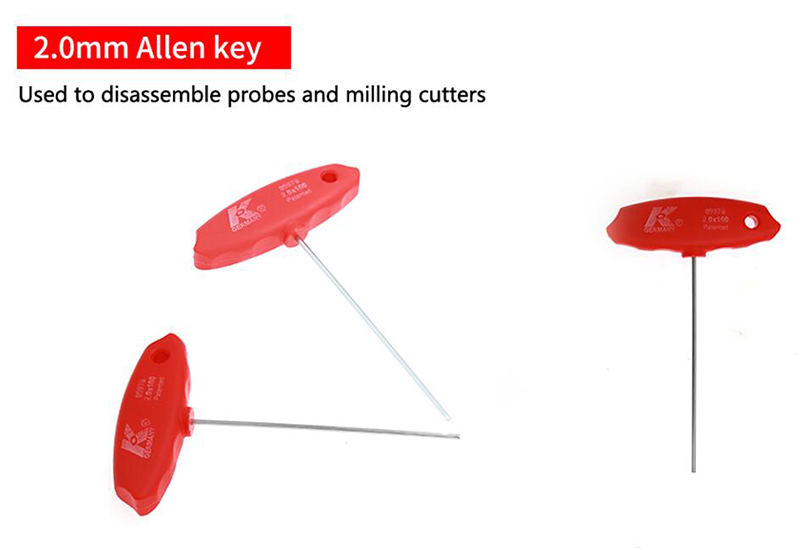

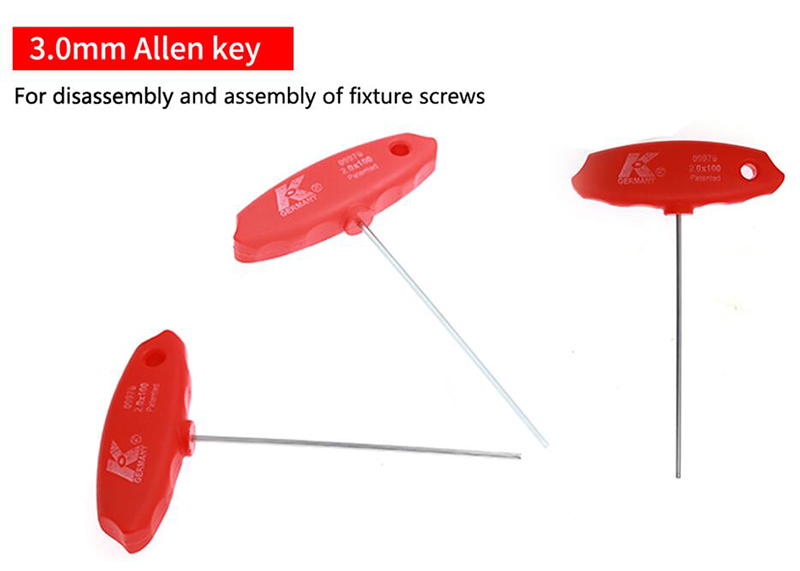

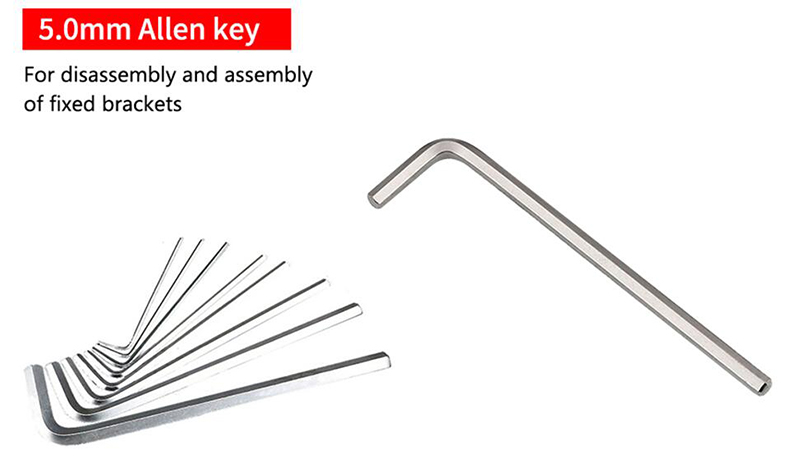

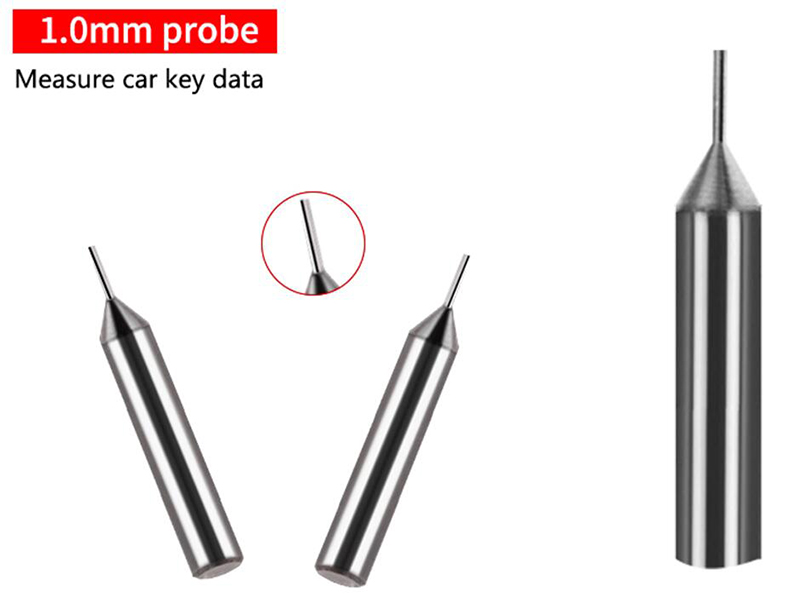

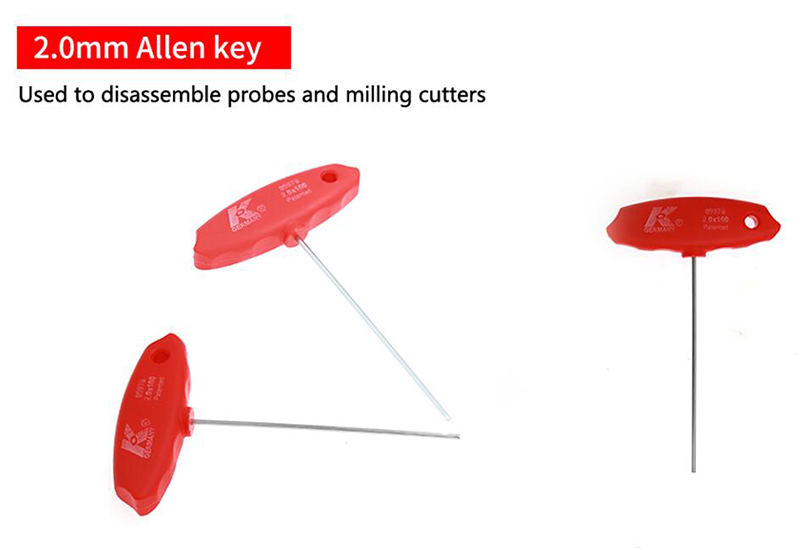

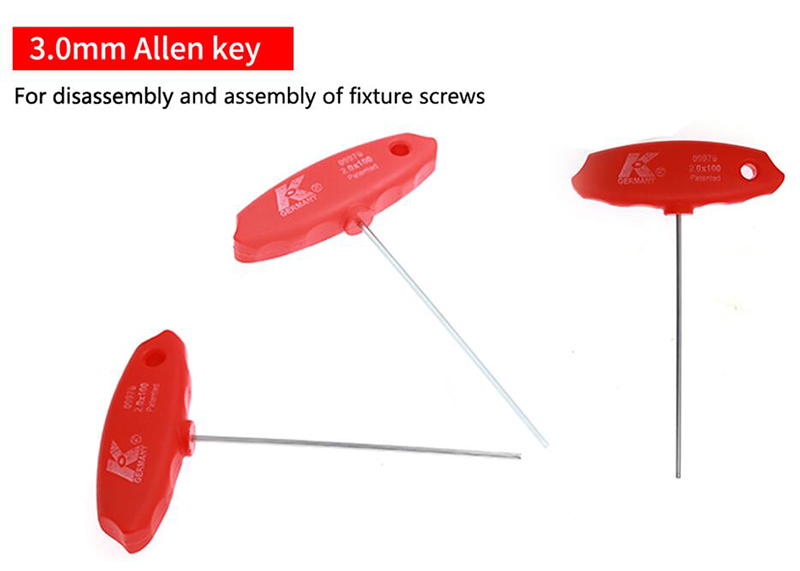

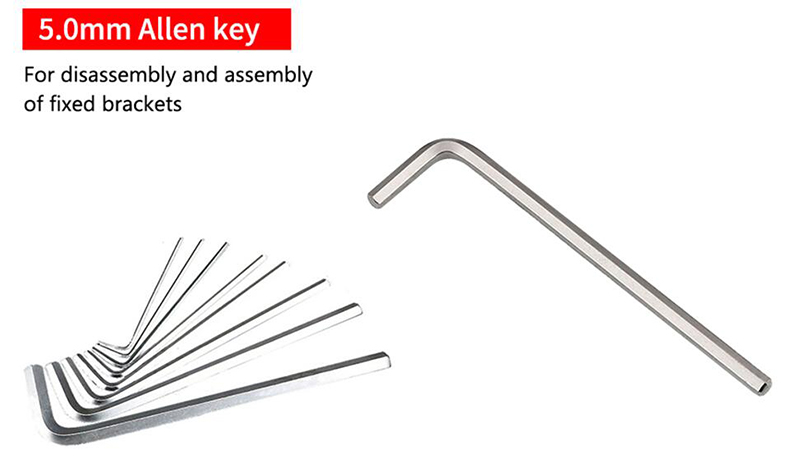

Accessories:

Operations